Qu’est-ce qu’un échafaudage supporté ? Types, avantages, inconvénients et utilisations

Dec 24, 2025

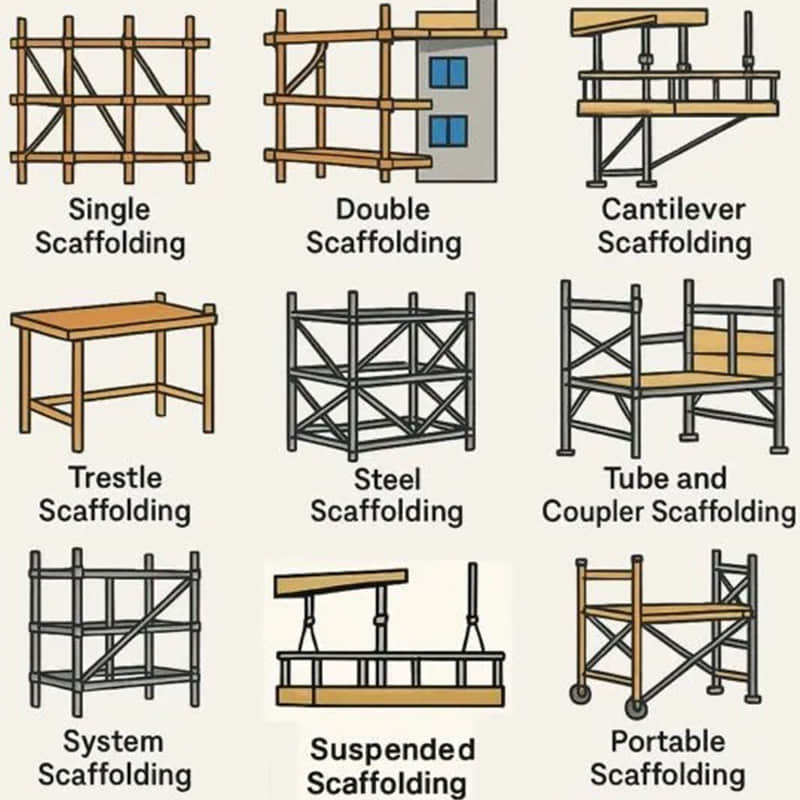

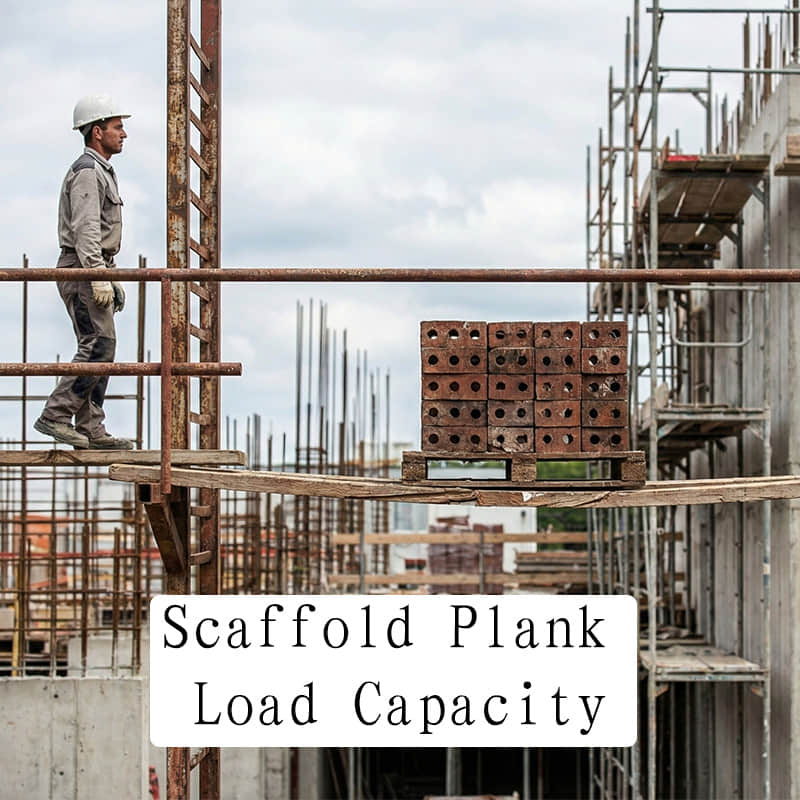

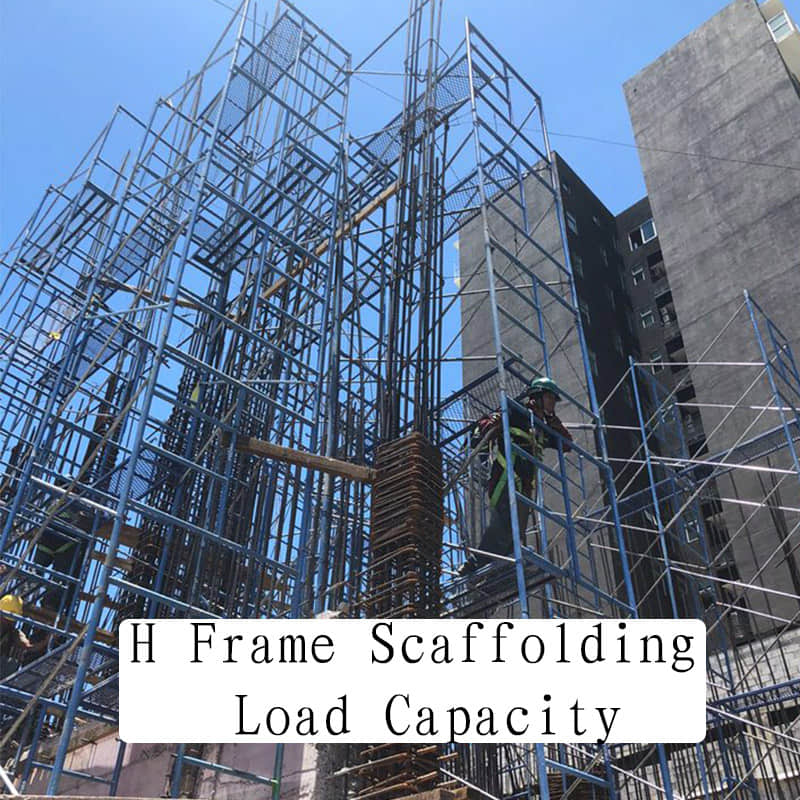

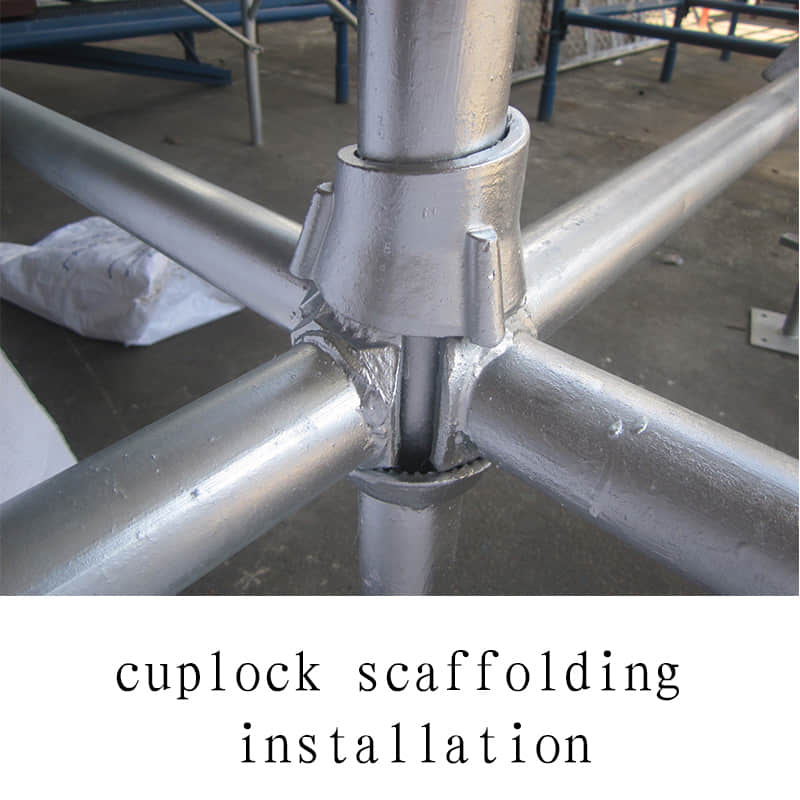

La sécurité et l'efficacité des travaux en hauteur sont des aspects essentiels du secteur de la construction. L'accès peut se faire par diverses méthodes, notamment les nacelles élévatrices, les plateformes suspendues, etc., mais la méthode traditionnelle de travail sur plateforme, appelée plateforme de travail en hauteur, reste la plus courante. échafaudage soutenu, est restée la méthode d'accès la plus basique et la plus utilisée au niveau mondial par les entrepreneurs.Si vous êtes chef de chantier, gérant d'une entreprise de location d'échafaudages ou responsable des achats dans votre secteur d'activité, comprendre le fonctionnement des échafaudages fixes, leurs avantages et leurs limites vous permettra de planifier vos projets efficacement. Ce guide vous fournira toutes les informations nécessaires pour choisir le matériel adapté à votre prochain projet d'échafaudage fixe. Qu'est-ce qu'un échafaudage supporté ? L'échafaudage supporté est la catégorie d'échafaudage qui supporte une ou plusieurs plateformes à l'aide d'éléments porteurs rigides (poteaux, pieds, cadres, montants, poteaux, stabilisateurs, etc.) pour supporter la plateforme et tous les matériaux, outils et travailleurs travaillant sur cette plateforme.Contrairement aux échafaudages suspendus, qui sont accrochés à un poteau de support aérien (comme dans les échafaudages de lavage de vitres), les échafaudages supportés sont placés sur un sol solide et fournissent tout le support de poids nécessaire pour transférer en toute sécurité le poids combiné des travailleurs, des outils et des matériaux au sol.De plus, il s'agit de la norme industrielle acceptée pour la construction de structures, les projets de maçonnerie lourde et de nombreux projets d'entretien à long terme dans lesquels les types de charges placées sur l'échafaudage nécessiteront des niveaux élevés de stabilité et de capacité portante. Types d'échafaudages supportés L’échafaudage supporté n’est pas une solution universelle. Il se décline en différentes configurations conçues pour répondre à des défis architecturaux spécifiques.1. Échafaudage à cadre fabriquéSouvent appelé simplement « échafaudage à ossature métallique », c'est le type le plus courant sur les chantiers résidentiels et commerciaux légers. Il se compose de cadres métalliques préfabriqués reliés par des entretoises transversales.Atout majeur : Montage et démontage extrêmement rapides.Idéal pour : murs linéaires, travaux de maçonnerie et plâtrage. 2. Échafaudage système (modulaire)Les systèmes d'échafaudage, tels que Ringlock, Cuplock ou Kwikstage, utilisent des poteaux verticaux et des traverses horizontales qui se connectent à des points nodaux fixes.Atout majeur : une flexibilité immense et une capacité de charge élevée.Idéal pour : les installations industrielles, les géométries complexes, les ponts et les structures circulaires. 3. Échafaudage tubulaire et à pincesCette méthode traditionnelle utilise des tubes et des raccords en acier. L'absence de points de verrouillage prédéfinis permet un réglage infini.Atout majeur : s’adapte à toutes les formes, même les plus irrégulières.Idéal pour : les raffineries et les zones fortement obstruées (tuyaux/conduits). 4. Échafaudages mobiles (Tours roulantes)Ce sont des échafaudages autoportants montés sur roulettes.Meilleur atout : la portabilité.Idéal pour : Les travaux de maintenance (peinture, électricité) où l'équipe doit se déplacer fréquemment sur un sol plat. Quels sont les avantages des échafaudages supportés ? La raison pour laquelle les ingénieurs et les responsables de chantier continuent d'utiliser des échafaudages fixes plutôt que des technologies plus récentes est simple : les échafaudages fixes offrent une plateforme incroyablement stable et sûre, avec la capacité de charge la plus importante. 1. Stabilité et sécurité exceptionnellesUn échafaudage fixe est un système ancré au sol où tout est solidement fixé : il n’y a aucun balancement et tout est parfaitement sécurisé. Cette stabilité offre aux travailleurs l’équilibre nécessaire pour réaliser des tâches exigeant une grande précision, comme la maçonnerie et la soudure, ce qui est essentiel pour un travail de qualité. 2. Capacité de charge élevéeConcernant les nacelles élévatrices, des limites de poids sont fixées (dans la plupart des cas, elles ne peuvent accueillir que deux ouvriers et leurs outils). Les échafaudages fixes, notamment ceux de type échafaudage à structure renforcée, sont conçus pour supporter des charges bien supérieures à celles des nacelles élévatrices. Ils permettent ainsi aux ouvriers de stocker simultanément des palettes de briques, de mortier, de poutres d'acier et plusieurs membres d'une équipe sur un même échafaudage. 3. Surface de travail spacieuseL'échafaudage autoportant facilite les déplacements sur les surfaces de travail d'un bâtiment. Ce type d'échafaudage supporte une plateforme de travail continue sur toute la longueur du bâtiment, permettant aux ouvriers de se déplacer sans avoir à s'arrêter pour régler leur équipement, ce qui améliore considérablement la productivité. 4. Valeur et durabilité à long termePour les entreprises de location, les échafaudages autoportants, principalement constitués d'acier galvanisé à chaud, offrent un excellent retour sur investissement. Résistants aux intempéries, ils ont une longue durée de vie et nécessitent peu d'entretien. Quels sont les inconvénients des échafaudages soutenus ? Pour prendre une décision éclairée, il faut également tenir compte des limites.1. Exigences fondamentalesPour être efficace, un échafaudage supporté nécessite une fondation stable. Une fondation stable est constituée d'une surface plane et suffisamment solide pour assurer la stabilité de l'échafaudage. Ainsi, lorsque la surface est irrégulière ou que le sol est meuble, on utilise des semelles et des plaques de base pour la construction des échafaudages, ce qui permet de minimiser les risques d'affaissement ou de basculement. 2. Empreinte au sol importanteLorsqu'un échafaudage est construit depuis le sol, sa base occupe de l'espace. Dans les villes denses où l'espace est insuffisant pour installer un échafaudage sur le trottoir ou devant un bâtiment, des autorisations spéciales et des passages piétons sécurisés sont nécessaires. 3. Durée de montage et de démontageContrairement à une nacelle élévatrice, opérationnelle dès sa livraison sur le chantier, un échafaudage fixe nécessite l'intervention d'un technicien qualifié pour son montage. Par conséquent, son installation et son démontage après la fin du projet requièrent une main-d'œuvre plus spécialisée, ce qui peut engendrer des coûts initiaux plus élevés. À quoi servent les échafaudages porteurs ? La polyvalence des échafaudages supportés les rend omniprésents dans de nombreux secteurs.1. Construction générale et génie civilDes immeubles résidentiels de grande hauteur aux complexes de bureaux, les échafaudages sont utilisés pour les travaux de structure, la pose de façades, la maçonnerie et l'installation de fenêtres. 2. Maintenance industrielleDans les centrales électriques, les raffineries de pétrole et les usines chimiques, les échafaudages de systèmes sont utilisés pour accéder aux chaudières, aux cheminées et aux systèmes de tuyauterie pour la maintenance de routine et les arrêts. 3. Projets d'infrastructureLa construction et la réparation des ponts reposent largement sur l'utilisation d'échafaudages pour créer des plateformes permettant aux ouvriers d'opérer sous ou le long du tablier du pont. 4. Construction navale et marineDes échafaudages sont installés autour des coques des navires dans les cales sèches, permettant aux équipes de souder, de peindre et de réparer ces navires massifs. 5. Structures publiques temporairesIl est intéressant de noter que les mêmes composants (notamment les systèmes Ringlock) sont souvent utilisés pour construire des tribunes, des scènes et des tours d'éclairage temporaires pour les concerts et les événements sportifs. Conclusion Dans le secteur de la construction, l'échafaudage à supports fixes est largement répandu. Bien que la planification des fondations et du temps de montage soit essentielle, ce type d'échafaudage présente de nombreux avantages : stabilité supérieure, capacité de charge élevée et sécurité accrue. Il s'avère ainsi le choix idéal pour les projets de moyenne et grande envergure. Pour les entreprises de construction, l'échafaudage à supports fixes garantit la sécurité des équipes ; pour les sociétés de location, il permet d'étoffer leur parc de matériel. Choisir l'échafaudage à supports fixes adapté est donc un facteur déterminant pour la réussite de votre activité. Modernisez vos solutions d'échafaudage dès aujourd'hui Vous recherchez des échafaudages fiables, certifiés et bénéficiant d'un support technique pour votre prochain projet ? Ou peut-être avez-vous besoin de renouveler votre stock de location avec des structures et des systèmes modulaires de haute qualité ?[Contactez notre équipe] Contactez-nous dès aujourd'hui pour obtenir des conseils d'experts et un devis compétitif adapté à vos besoins spécifiques. FAQ Quelle est la hauteur maximale autorisée pour un échafaudage supporté ?En théorie, les échafaudages autoportants peuvent atteindre des hauteurs importantes, à condition que leur base soit suffisamment solide. Cependant, les normes de sécurité en vigueur (comme celles de l'OSHA) imposent un rapport hauteur/base strict (généralement 4:1) afin d'éviter tout basculement. Si un échafaudage dépasse ce rapport, il doit être solidement ancré à la structure du bâtiment à l'aide de tirants, d'haubans ou d'entretoises. Pour les structures de très grande hauteur (plus de 38 mètres), la conception du système requiert généralement l'intervention d'un ingénieur spécialisé. À quelle fréquence faut-il inspecter les échafaudages porteurs ?Conformément aux normes de sécurité, les échafaudages supportés doivent être inspectés par une personne compétente avant chaque prise de poste et après tout événement susceptible d'affecter leur intégrité structurelle (comme une tempête ou un impact). Ces inspections régulières permettent de vérifier la stabilité des plaques de base, le serrage des fixations et l'absence de dommages aux composants. Puis-je mélanger des éléments d'échafaudage provenant de différents fabricants ?Il est généralement déconseillé de mélanger des composants provenant de différents fabricants, même s'ils semblent similaires. De légères variations de tolérance, de nuance d'acier ou de mécanismes de verrouillage peuvent compromettre l'intégrité structurelle. Si ce mélange s'avère nécessaire, il doit être approuvé par un ingénieur qualifié afin de garantir un assemblage sûr et le maintien de la capacité de charge.