Qu’est-ce que le coffrage et pourquoi est-il l’épine dorsale de la construction en béton ?

Jul 09, 2025Surnommé « bâtisseur invisible », le coffrage est le moule, temporaire ou permanent, dans lequel le béton frais est coulé et maintenu en place jusqu'à ce qu'il ait durci et acquis une résistance suffisante pour se soutenir. Il est essentiel à la construction en béton : il maintient sa forme, assure le soutien et assure la finition du produit final. Sans coffrage, nous ne pourrions pas créer les magnifiques bâtiments dans lesquels nous vivons et travaillons, ni les infrastructures nécessaires au fonctionnement de la société telle que nous la connaissons.

Dans cet article, nous discuterons du monde du coffrage, de son objectif, des différents types de coffrage sur le terrain, des principaux composants et du séquençage qui doit avoir lieu pour atteindre l'intégrité structurelle et la sécurité.

Intégrité structurelle : Le coffrage permet de créer la taille et la forme adéquates pour les éléments structurels tels que les poutres et les poteaux, ce qui influence directement la résistance et la sécurité du bâtiment. Un coffrage incorrect peut entraîner des problèmes structurels, voire l'effondrement du bâtiment.

Précision dimensionnelle : Les dimensions du projet doivent être précises pour assurer l'assemblage correct des autres éléments du bâtiment, une répartition optimale des charges et un aspect esthétique agréable. Le coffrage garantit la conformité de l'élément final en béton aux spécifications de conception.

Finition de surface : La surface intérieure du coffrage influence directement la texture et l'esthétique du béton fini. Nous proposons des coffrages produisant des surfaces lisses, rugueuses ou à motifs, selon les spécifications de la conception.

Sécurité : Lors de la conception et de la construction d'un coffrage, la sécurité des ouvriers sur le chantier est essentielle. Le coffrage doit être suffisamment solide pour résister à la pression du béton humide, ainsi qu'aux charges vives des équipements et du personnel. Une défaillance du coffrage peut entraîner des blessures graves, voire mortelles.

Efficacité et économie : Bien que le coffrage soit une structure temporaire, la conception et l'installation ont une influence significative sur la durée et les coûts du projet. Les systèmes de coffrage permettent de gagner en efficacité et de réduire considérablement le temps de chantier et les coûts de main-d'œuvre.

Le coffrage a beaucoup évolué depuis les simples planches de bois utilisées par les Romains. Il existe aujourd'hui une multitude de matériaux et de systèmes techniques aux propriétés spécifiques, adaptés à des projets de toutes tailles, de tous budgets et de tous besoins architecturaux.

Le coffrage en bois est le type de coffrage le plus conventionnel et le plus courant ; il est fabriqué à partir de bois et de contreplaqué.

Ces systèmes de panneaux préfabriqués offrent une efficacité globale accrue et une meilleure réutilisabilité. La plupart des systèmes de coffrage technique sont constitués d'un cadre en acier ou en aluminium avec un revêtement posé ou collé en contreplaqué, en acier ou en matériaux composites.

Les coffrages en acier sont fabriqués à partir de panneaux et de composants en acier et sont connus pour leur résistance et leur durabilité.

Le coffrage en aluminium est un choix populaire dans le secteur de la construction résidentielle et commerciale. Il présente de nombreux avantages par rapport à l'acier, avec une différence notable.

Une idée plus moderne, il s'agit d'un coffrage réalisé à partir de panneaux en plastique légers et emboîtables.

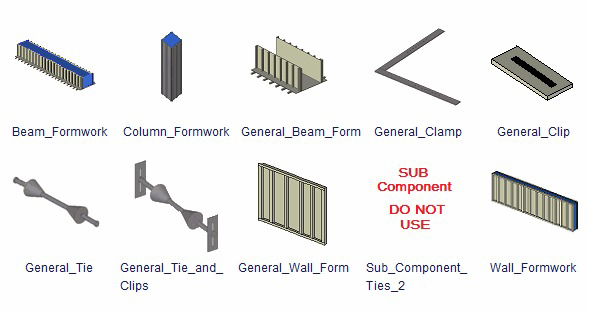

Quel que soit le matériau, la plupart des systèmes de coffrage comprennent plusieurs composants essentiels :

Le cycle de vie d'un coffrage sur un projet est une opération précise :

Compte tenu des charges considérables qu'ils supportent, les défaillances des coffrages peuvent être catastrophiques, entraînant des blessures, des décès et des retards importants sur les chantiers. La sécurité est donc primordiale. Cela implique une conception méticuleuse par des ingénieurs qualifiés, l'utilisation de matériaux appropriés et bien entretenus, un assemblage soigné par une main-d'œuvre qualifiée et une inspection continue avant, pendant et après le coulage du béton.

Pourquoi la sécurité des coffrages est-elle si importante ?

Les coffrages supportent un poids considérable. La pression exercée par le béton humide est importante, et l'ensemble du système supporte également le poids des ouvriers et des équipements. L'effondrement d'un coffrage est une défaillance catastrophique pouvant entraîner :

Blessures graves et décès.

Retards majeurs dans les projets et pertes financières.

Défauts structurels dans le bâtiment.

Le coffrage peut-il être réutilisé ?

Oui, la réutilisabilité est un facteur clé des coffrages modernes. Le nombre de réutilisations d'un coffrage dépend entièrement du matériau qui le compose et de son entretien :

Coffrage en bois : peut généralement être réutilisé 5 à 10 fois.

Coffrage en plastique : Souvent réutilisable plus de 100 fois.

Coffrages en aluminium et en acier : peuvent être réutilisés des centaines, voire des milliers de fois avec un entretien approprié, ce qui les rend idéaux pour les constructions répétitives à grande échelle.

Coffrage —— YouTube

Comment construire un coffrage —— YouTube