Introduction

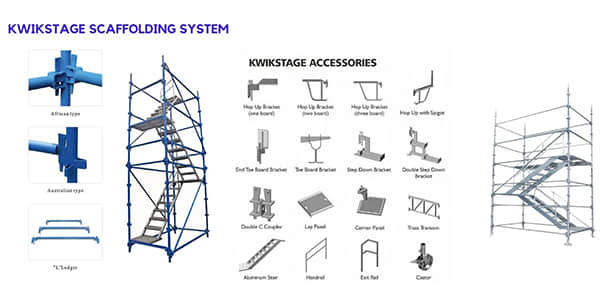

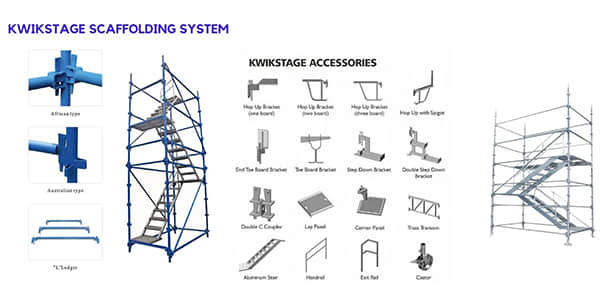

Dans le monde de la construction en constante évolution, il est impossible d'être trop efficace, trop sûr ou trop fiable. Système d'échafaudage Kwikstage Tout cela est possible, et bien plus encore ! L'échafaudage Kwikstage est un système global modulaire et préfabriqué, rapide à monter et à démonter. Plus rapide que d'autres systèmes, car les systèmes traditionnels à tubes et raccords sont lourds et encombrants. Le terme « kwikstage » a été choisi pour ce produit afin de souligner sa rapidité de montage par rapport à toute autre méthode de réalisation. Plus généralement, son utilisation permet de réaliser des économies de temps et de main-d'œuvre considérables sur chantier ; un avantage concurrentiel incontestable.

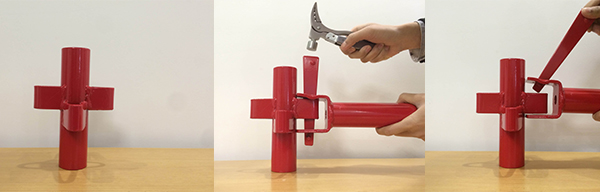

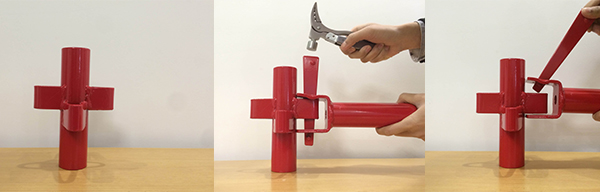

Kwikstage se distingue par son système unique de fixation par coin. Chaque composant s'emboîte, ce qui vous permet de prendre la fixation pour le clouage et de la réaligner au fur et à mesure. Il suffit d'abattre toute tige verticale au marteau ; inutile donc de recourir à des fixations, des clés ou des boulons. Ce système permet également un assemblage plus sûr et plus simple, tout en offrant une structure très solide et stable.

Que vous soyez chef de projet, chef de chantier ou ouvrier qualifié, une fois que vous aurez compris comment monter correctement un échafaudage Kwikstage, vous pourrez aider vos équipes à créer un environnement de travail sûr et productif. Ce guide est une version complète de la procédure. monter un échafaudage Kwikstage des descriptions des composants aux contrôles de sécurité.

Partie 1 : Qu'est-ce que l'échafaudage Kwikstage ?

Comprendre les éléments avant de construire. Kwikstage n'est pas un amas de poteaux ; c'est un échafaudage technique. Les éléments essentiels sont standardisés et durables, et s'intègrent parfaitement.

Composants clés :

- Normes (verticales) : Il s'agit des principaux poteaux porteurs verticaux, sur lesquels sont soudés des « V-pressés » ou coupelles, espacés (généralement tous les 500 mm ou 1 000 mm, conformément à la norme industrielle). Ces emboutis sont essentiels car ils servent à l'assemblage d'autres composants.

- Grands livres (horizontaux) : Il s'agit d'éléments horizontaux reliant les montants et définissant la longueur de la travée de l'échafaudage. Les têtes de coin s'insèrent dans les emboutis en V des montants.

- Traverses : Elles relient les montants sur toute la largeur de la baie et soutiennent les planches de la plate-forme de travail.

- Accolades diagonales : Important pour la stabilité et la rigidité de l'ensemble du cadre et empêche effectivement l'échafaudage de se balancer ou de tomber latéralement.

- Panneaux d'acier : Les plateformes de travail sont sûres pour le personnel et le matériel et sont antidérapantes.

- Crics de base et planches de semelle : Les vérins de base s'ajustent pour permettre à l'échafaudage d'être de niveau sur le sol irrégulier, tandis que les planches de semelle partagent la charge et empêchent le poids des normes de s'effondrer ou de s'enfoncer dans le sol irrégulier.

La nature standardisée de ces pièces permet un assemblage rapide et précis, réduisant considérablement les risques d’erreur humaine par rapport aux systèmes traditionnels.

Partie 2 : Le processus d'érection : un guide de sécurité étape par étape

Le processus de montage d'un échafaudage Kwikstage est une séquence exacte et répétable qui doit être suivie attentivement afin de fournir un échafaudage sûr et structurellement solide.

Étape 1 : Inspection du site et des composants avant le montage

La sécurité commence avant même la pose d'une seule pièce.

- Évaluation du site : Une personne compétente doit évaluer le terrain sur lequel sera installé l'échafaudage. Ce terrain doit être solide, plat et capable de supporter la charge de l'échafaudage.

- Vérification des composants : Vérifiez que tous les supports, les registres et les entretoises ne présentent aucun dommage, notamment des bosses, des courbures et des fissures. N'utilisez pas d'articles endommagés.

- Compétence de l'équipe : Vérifiez que tous les membres de l’équipe ont la formation et la certification pour pouvoir travailler avec Kwikstage.

Étape 2 : Installation de la base

La base est primordiale. Un échafaudage correctement nivelé est un échafaudage sûr.

- Localiser les planches de semelle : Positionnez les planches de semelle exactement comme indiqué dans la conception de l'échafaudage.

- Installer les crics de base : Placez les vérins de base réglables sur la semelle. Utilisez un niveau à bulle pour vous assurer que la hauteur variable et la hauteur du vérin sont d'aplomb et de niveau afin de tenir compte des variations du sol.

- Positionner les premières normes : Placez les premiers standards directement sur les vérins de base.

Étape 3 : Construction de la première travée (ascenseur)

C'est ici que la magie opère.

- Connecter les registres : Connectez les montants en insérant les têtes des coins des longrines dans les empreintes en V. À l'aide d'un marteau lourd, enfoncez fermement les coins et verrouillez la connexion.

- Ajouter des traverses : Fixez les traverses pour relier les montants sur toute la largeur de la baie.

- Vérifier et équerrer : Avant de continuer, utilisez un ruban à mesurer et un niveau à bulle pour confirmer que la baie est carrée et de niveau.

Étape 4 : Installation des supports diagonaux

Le contreventement est ce qui rend la structure rigide.

- Fixer les accolades : Fixez les entretoises diagonales aux emboutis en V des montants à un angle, à la fois sur la face de l'échafaudage et périodiquement sur les extrémités.

- Importance: L'une des principales raisons de l'instabilité des échafaudages est l'installation inadéquate ou incorrecte des contreventements. Or, ces derniers sont essentiels.

Étape 5 : Mise en place des plateformes et installation des dispositifs de sécurité

Une fois le cadre fixé, vous pouvez créer la surface de travail.

- Installer les cartes : Placez les planches d'acier sur les traverses. Assurez-vous qu'elles sont bien en place et qu'elles ne bougent pas.

- Installer des garde-corps : Sur une plateforme de travail de plus de 2 mètres, installer un garde-corps supérieur et un garde-corps médian.

- Installer les plinthes : Vous devez utiliser des plinthes autour du bord de la plate-forme pour empêcher les outils et les matériaux de rouler.

Étape 6 : Extension vers le haut (érection des levées suivantes)

Pour aller plus haut, vous répétez le processus.

- Normes de connexion : Utilisez des robinets pour connecter le prochain ensemble de normes au-dessus du premier.

- Répéter: Suivez le même processus pour connecter les grands livres, les traverses et les supports diagonaux.

- Liens : Il s'agit d'une étape cruciale et non négociable. À mesure que l'échafaudage s'élève, il doit être ancré au bâtiment ou à une structure solide à intervalles réguliers pour éviter son effondrement. La fréquence des ancrages est déterminée par le plan de conception de l'échafaudage.

Partie 3 : Règles et réglementations essentielles en matière de sécurité

La construction d'un échafaudage ne se limite pas à l'assemblage des composants. Il s'agit également de respecter les protocoles de sécurité.

- Conformité réglementaire : Respectez toujours les réglementations nationales et locales, telles que les normes OSHA aux États-Unis ou AS/NZS 1576 en Australie.

- Inspections régulières : Les échafaudages doivent être inspectés avant chaque utilisation et après tout événement pouvant affecter leur intégrité, comme une tempête ou des vents violents.

- Accès et sortie : Assurez-vous qu’il existe un moyen sûr et clair d’accéder à l’échafaudage, comme une échelle ou un escalier désigné.

- Démontage en toute sécurité : Une fois le travail terminé, l'échafaudage doit être démonté dans l'ordre inverse de son montage, en commençant du haut vers le bas.

Conclusion

L'installation d'un échafaudage Kwikstage est un processus sûr et efficace, à condition d'être effectué avec les connaissances nécessaires et le souci du détail. Sa conception et sa simplicité d'utilisation en ont fait un pilier du secteur de la construction moderne. En suivant une procédure claire et étape par étape et en privilégiant la sécurité à chaque étape, vous pouvez construire une structure stable et fiable qui protège votre équipe et votre projet.

Besoin d'échafaudages Kwikstage pour votre prochain projet ? Nous proposons une gamme complète de produits de haute qualité. Composants Kwikstage à vendre, ainsi que des conseils d'experts pour garantir que votre projet soit construit de manière sûre et efficace. Contactez-nous aujourd'hui pour obtenir un devis et découvrir comment nos solutions peuvent soutenir votre réussite.

FAQ

L'échafaudage Kwikstage est-il sûr ?

- Oui, c’est l’un des systèmes les plus sûrs disponibles lorsqu’il est érigé par des professionnels certifiés et entretenu correctement.

En quoi diffère-t-il des échafaudages traditionnels ?

- Kwikstage est modulaire, utilise un système de fixation rapide par cale et est beaucoup plus rapide à monter et à démonter que les systèmes traditionnels à tubes et coupleurs.

Kwikstage peut-il être utilisé pour n’importe quelle taille de projet ?

- Oui, sa conception modulaire le rend adapté aussi bien aux petits travaux résidentiels qu'aux projets commerciaux à grande échelle.

Quel poids peut-il supporter ?

- La capacité de charge spécifique dépend de la configuration, mais le système est conçu pour supporter en toute sécurité plusieurs travailleurs et des matériaux lourds.