Capacité de charge des échafaudages à cadre en H : sécurité, normes et meilleures pratiques

Dec 09, 2025échafaudage à cadre en H (Section/ échafaudage à ossature maçonnique) est un échafaudage de construction nécessaire et courant, fournissant la charge de travail, l'accès et la mobilité nécessaires à une variété de projets de construction, du résidentiel au commercial, en passant par les grandes infrastructures publiques.

Pour qu'un chantier soit sûr, la seule chose qui soit absolument indispensable, c'est l'échafaudage. L'intégrité structurelle de tout projet de construction repose entièrement sur la capacité de charge de l'échafaudage.

Le calcul de la capacité de charge des échafaudages à cadre en H constitue une obligation légale et morale. Négliger ce calcul peut entraîner l'effondrement total de la structure, des blessures graves, voire mortelles. C'est pourquoi ce guide détaillé, destiné aux chefs de chantier, aux ingénieurs et aux entreprises de location de matériel, présente les normes, les paramètres et les bonnes pratiques pour une utilisation sécuritaire des échafaudages à cadre en H.

Avant d'analyser la capacité de charge d'une structure, il est essentiel d'établir une terminologie standardisée. Une mauvaise compréhension de ces termes est une cause majeure de surcharge extrême.

Charge de travail (CT), ou charge admissible – La charge maximale (humaine, matérielle, outils) que l’échafaudage a été conçu et approuvé pour supporter en toute sécurité lors d’une utilisation quotidienne, est généralement obtenue en divisant la charge ultime par le facteur de sécurité.

Charge nominale – Désigne une classification de capacité établie par le fabricant ou selon la norme de conception. Les classifications des charges nominales sont courantes aux États-Unis et dans le monde entier, et sont très souvent liées au poids réparti par pied carré/mètre carré.

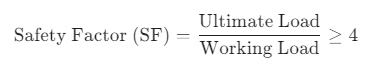

La conception sécuritaire des échafaudages est essentielle pour garantir leur intégrité structurelle et leur performance. Le coefficient de sécurité (CS) sert de base à cette évaluation et est défini par les réglementations fédérales (OSHA) et étatiques. Le CS doit garantir que, lors de l'exécution d'une tâche donnée à l'aide d'un échafaudage, celui-ci puisse supporter en toute sécurité, au minimum, son propre poids majoré de quatre fois la charge maximale prévue.

Le rapport 4:1 offre également une marge de sécurité pour les matériaux utilisés, les petites variations lors du montage de l'échafaudage et la dynamique des charges. Ainsi, les charges de travail de l'échafaudage ne dépasseront jamais 25 % de sa capacité nominale finale (charge ultime).

La capacité de charge réelle d'un échafaudage à cadre en H monté est une variable complexe, influencée par plusieurs facteurs interdépendants qui vont bien au-delà de la capacité nominale initiale du fabricant.

La solidité du noyau repose sur ses composants eux-mêmes :

La manière dont l'échafaudage est assemblé détermine sa stabilité et sa capacité :

Il s'agit souvent du facteur le plus négligé dans les défaillances liées à la charge.

Contreventements transversaux et diagonaux : ces éléments transforment les cadres individuels en une structure rigide et monolithique. Ils empêchent la déformation latérale des cadres sous l’effet d’une charge verticale ou de la force du vent. Un échafaudage sans contreventements diagonaux continus et adéquats présente une capacité de charge fortement compromise.

Fixation à la structure : Les échafaudages dépassant une certaine hauteur (souvent quatre fois leur largeur à la base) doivent être solidement fixés à la structure permanente du bâtiment. Ces fixations empêchent le balancement latéral et le flambement, transmettent les charges horizontales dues au vent et contribuent à la stabilité générale, essentielle pour optimiser la capacité de charge verticale.

La stabilité d'un échafaudage dépend de la stabilité du sol sur lequel il repose.

Plaques de base et semelles : Chaque pied doit reposer sur une semelle afin de répartir la charge verticale. Si le sol est meuble, la semelle doit reposer sur des semelles robustes (semelles en terre ou semelles de fondation, généralement en bois) afin de répartir la charge sur une plus grande surface et de réduire la pression au sol à un niveau acceptable.

Capacité portante du sol : Il convient d’évaluer la capacité du sol à résister à la pression des pieds de l’échafaudage. Un tassement inégal du sol entraîne des déformations, créant des charges excentrées et des contraintes internes qui réduisent considérablement la charge admissible de l’échafaudage.

Les responsables de la construction doivent systématiquement estimer la charge totale avant utilisation :

charge morte: Le poids des composants de l'échafaudage eux-mêmes (fourni par le fabricant/fournisseur).

Charge utile (Charge à supporter):

Charges environnementalesPrincipalement les charges dues au vent. Les vents violents peuvent générer d'énormes forces latérales (horizontales) qui, si elles ne sont pas contrées par des contreventements et des ancrages adéquats, peuvent provoquer des déformations et des ruptures, même si la charge verticale est faible.

Ne vous fiez jamais aux suppositions. Si la charge totale estimée approche la limite de charge moyenne du fabricant, consultez un ingénieur en échafaudages certifié afin de vérifier la conception et la capacité réelle de votre configuration spécifique.

Le déploiement sécuritaire des échafaudages à cadre en H repose sur une compréhension approfondie et professionnelle de leur capacité de charge. Cet engagement s'étend de la conception technique initiale et de la qualité du matériel loué jusqu'aux inspections quotidiennes effectuées par les chefs de chantier. En respectant le coefficient de sécurité de 4:1, en vérifiant méticuleusement les contreventements et les fondations et en appliquant des protocoles stricts de gestion des charges, les entreprises de construction et les fournisseurs de location peuvent garantir la sécurité, la conformité et la solidité structurelle de leurs plateformes. La sécurité n'est pas une option ; elle est le fondement sur lequel doit reposer tout projet de construction réussi.

Quelle est la principale cause d'effondrement d'échafaudages sous l'effet de la charge ?

Puis-je dépasser temporairement la limite de charge de travail ?