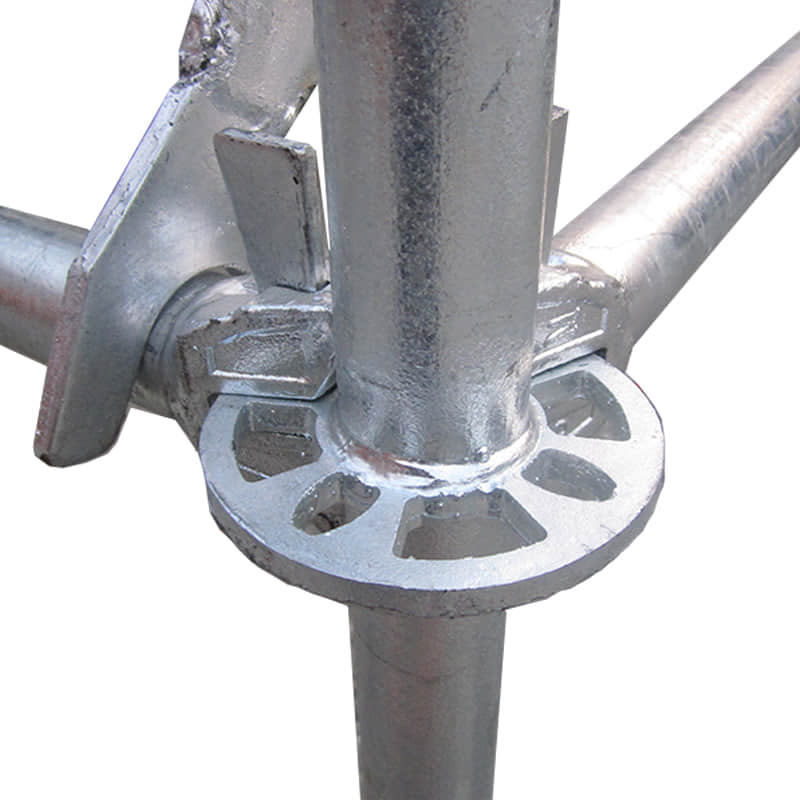

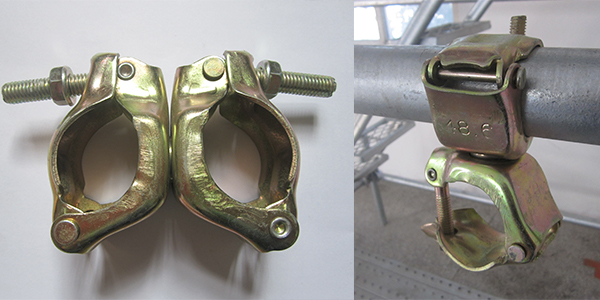

Le coupleur pivotant, également appelé collier pivotant, est un composant essentiel des systèmes d'échafaudage. Sa conception unique permet de connecter les tubes d'acier d'échafaudage sous n'importe quel angle, offrant une flexibilité et une sécurité exceptionnelles pour les structures complexes et les projets aux formes spéciales.

Que votre projet concerne un chantier de grande envergure ou un simple projet de maintenance, le choix du connecteur d'échafaudage adapté est crucial pour garantir sécurité et efficacité. Nos coupleurs pivotants sont fabriqués conformément aux normes internationales EN74 et BS1139 et sont disponibles en versions embouties, forgées et moulées pour répondre à vos besoins variés.

Spécifications du produit

- Taper: Pressé, forgé, moulé

- Diamètre de tuyau applicable : 42 mm, 48 mm, 60 mm, 76 mm, 89 mm (ou autres tailles personnalisées)

- Normes : EN74, BS1139

- Traitement de surface : Électro-galvanisé, galvanisé à chaud, peint

Types de coupleurs pivotants

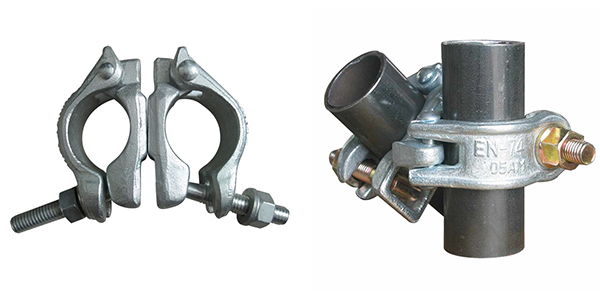

Pressé Coupleur pivotant

Les attaches estampées sont fabriquées en découpant une tôle d'acier, en la chauffant, puis en l'emboutissant à l'aide d'une matrice.

Caractéristiques:

- Léger : Par rapport aux fixations forgées, les fixations estampées sont plus légères et plus faciles à manipuler et à installer.

- Coût inférieur : le processus de production est hautement automatisé, le coût de production est donc relativement faible.

Forgé Coupleur pivotant

Les fixations forgées sont formées en plaçant une billette d'acier chauffée dans une matrice et en la forgeant à plusieurs reprises à l'aide d'un marteau ou d'une presse à haute pression. Ce procédé modifie la structure interne de l'acier, rendant ses grains plus denses et plus uniformes.

Caractéristiques:

- Haute résistance : Le processus de forgeage élimine les pores et les défauts internes, conférant aux fixations une résistance à la traction et une durabilité extrêmement élevées, capables de supporter des charges et des impacts plus importants.

- Haute sécurité : En raison de leurs excellentes propriétés mécaniques, les fixations forgées sont largement utilisées dans les points de connexion porteurs clés, tels que la connexion entre les poteaux verticaux et les poteaux horizontaux.

- Longue durée de vie : Résiste à la déformation et à la fatigue, ce qui se traduit par une durée de vie plus longue.

- Coût plus élevé : le processus de production est relativement compliqué et le coût est également plus élevé.

Coupleur pivotant moulé

Les fixations moulées sont formées en versant du métal en fusion (généralement de la fonte ductile) dans un moule et en le laissant refroidir et se solidifier.

Caractéristiques:

- Production flexible : des fixations aux formes complexes peuvent être fabriquées.

- Risque de fragilité : La structure interne des pièces moulées n'est pas aussi étanche que celle des pièces forgées et peut contenir de minuscules pores. Elles peuvent être plus fragiles que les pièces forgées lorsqu'elles sont soumises à une forte pression ou à un impact.

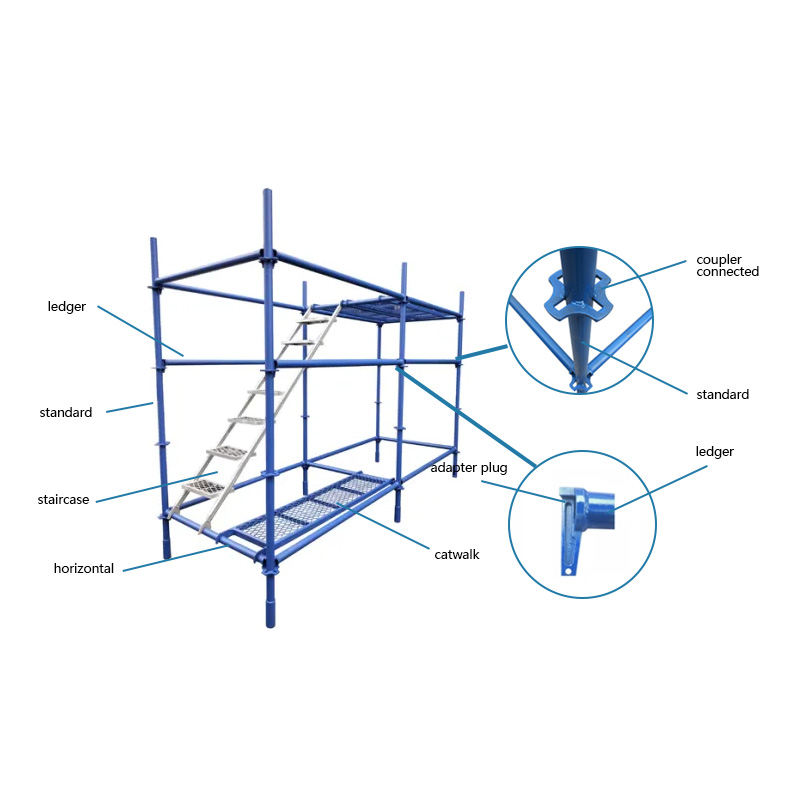

Scénario d'application

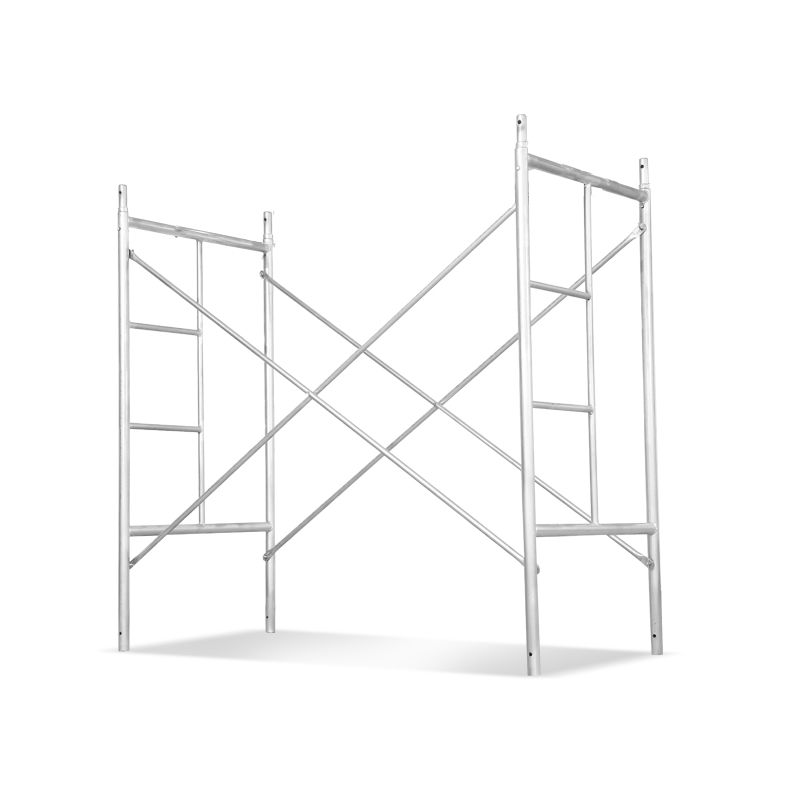

Échafaudage à structure complexe : Dans les projets tels que les ponts, les tunnels et les viaducs qui nécessitent des contreventements diagonaux et des structures courbes, les connecteurs universels sont la clé pour assurer la sécurité et la stabilité.

Construction de la scène et du spectacle : construisez rapidement des fermes de scène, des supports d'éclairage et des murs de fond de différentes formes, offrant un haut degré de liberté.

Tribunes et gradins temporaires : Fournir des tribunes temporaires stables et flexibles et des sièges pour spectateurs pour des événements à grande échelle.Projets spéciaux : Convient à tous les projets de construction, d'entretien et de décoration qui nécessitent le raccordement flexible de tuyaux en acier.

en

en fr

fr es

es