Formé traditionnel: un guide complet des systèmes de bois et de contreplaqué

Le coffrage est devenu synonyme de construction en béton, façonnant les structures en béton tout en garantissant la force et la durabilité. La construction de coffrage conventionnelle basée principalement sur le bois et le contreplaqué - est indispensable dans la construction, en particulier en ce qui concerne les travaux sur mesure et les projets à faible budget. Ce guide couvrira les composants individuels de ces deux systèmes de coffrage basés sur le bois, leurs diverses applications et leur endurance.

Examen rapide du coffrage traditionnel

Le coffrage conventionnel est une tradition où les moules temporaires sont fabriqués à partir de bois, de planches et de contreplaqué pour soutenir le béton humide jusqu'à ce que le réglage se produise. Contrairement aux systèmes modulaires avancés d'aujourd'hui, le coffrage conventionnel est construit sur place, permettant ainsi une grande flexibilité des formes et des tailles. Même si des technologies plus récentes sont disponibles, le coffrage en contreplaqué et en cannette continue d'être populaire parmi les projets de petits à-médiations en raison de son abordabilité relative, de sa facilité d'utilisation et de son adaptabilité.

Une brève histoire du coffrage traditionnel

Le bois a une ancienne tradition pour son application dans le coffrage. Par exemple, les ingénieurs romains ont utilisé des moisissures en bois pour créer les célèbres dômes coniques du Panthéon. Avec l'émergence du contreplaqué au 20e siècle, les conventions établies de coffrage ont été allumées et remplacées par des concepts modernes de finition plus fluide et de réutilisabilité maximale. Aujourd'hui, malgré toutes les nouvelles avancées, les systèmes de bois et de contreplaqué sont encore fermement ancrés dans la culture de la construction dans de nombreux endroits, en particulier dans ceux qui apprécient l'efficacité et la construction à la main.

Exigences générales pour le coffrage traditionnel

Les exigences communes pour que le coffrage traditionnel soit efficace sont:

- Force: soutenir le poids du béton fraîchement versé (jusqu'à 150 kN / m³).

- Rigidité: ne devrait pas se plier ou se déformer pendant la coulée.

- Stabilité: résister aux forces externes comme l'activité du vent ou des travailleurs.

- Précision: conforme aux dimensions fixes des plans de conception.

- Réutilisabilité: optimiser la réutilisation des matériaux pour les économies de coûts.

- Effectif: minimiser les coûts de main-d'œuvre et de matériel.

- Sécurité: protéger les travailleurs lorsque vous travaillez.

Matériaux principaux utilisés:

- Titre: Matériel pour former un cadrage structurel (goujons, poutres et accessoires).

- Plywood: responsable de la finition du béton contre une surface lisse (18-25 mm d'épaisseur).

- Formez des liens: tiges métalliques (attaches en instant, liens de bobine) à la pression latérale.

Systèmes de coffrage traditionnels typiques

Le formulaire traditionnel diffère selon l'élément structurel particulier impliqué. Vous trouverez ci-dessous quelques murs, colonnes et dalles typiques:

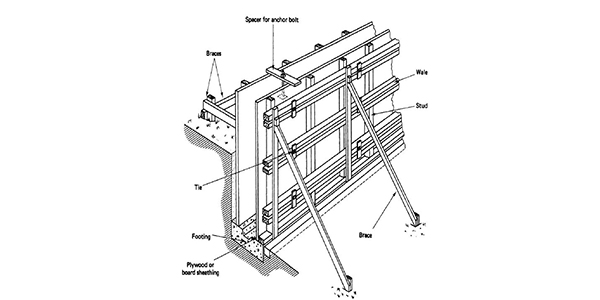

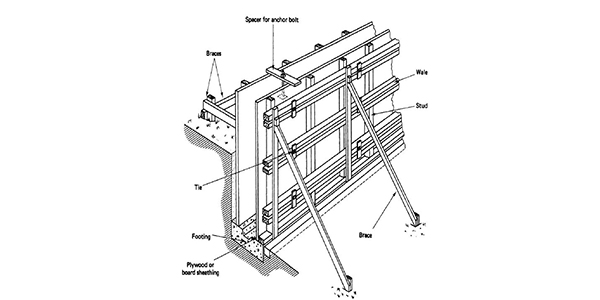

Coffrage pour les murs

Le coffrage pour les murs se compose de cadres en bois couverts de revêtement en contreplaqué:

- Faire du revêtement: est la surface du panneau de contreplaqué qui est généralement comprise entre 18 et 25 mm d'épaisseur.

- Clous et Pays de Galles: les clous en bois vertical soutiennent le revêtement en contreplaqué et le Pays de Galles horizontaux tels que le bois 2x4 ou 4x4 contre eux.

- Formes de forme: les liens métalliques tels que les attaches en instant ou les liens de bobine maintiennent les deux faces de contreplaqué opposées ensemble et résistent à la pression du béton versé.

- Braces: Braces en bois disposées en diagonale assurer la verticalité et résister à l'épaule bombée.

Meilleures pratiques:

- Utilisez du contreplaqué avec une surface lisse pour éviter les finitions en béton rugueux.

- Scellez les joints entre des feuilles de contreplaqué avec du ruban adhésif ou du silicone pour éviter les fuites.

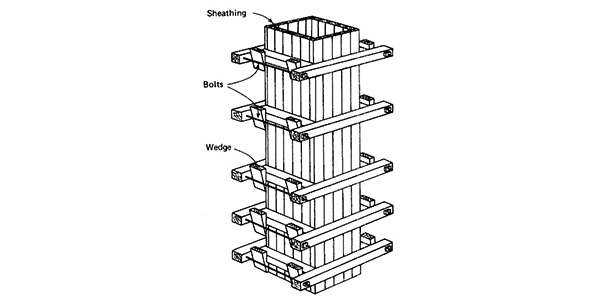

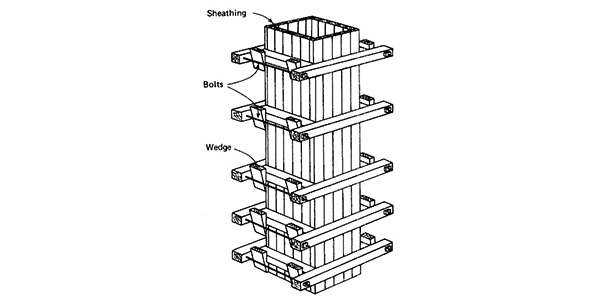

Coffrage des colonnes

Le coffrage des colonnes exige une précision pour les formes carrées, rectangulaires ou circulaires:

- Repasser: panneaux de contreplaqué coupés pour correspondre aux dimensions de la colonne.

- Yokes et pinces: les lattes en bois ou les pinces métalliques resserrent le coffrage pour éviter les éruptions.

- Renforcement: les raidisseurs verticaux en bois (lattes 2x4) renforcent le contreplaqué contre la pression du béton.

Conseil de pro: Appliquez du formulaire d'huile ou de graisse sur des surfaces en contreplaqué pour un déshabillage plus facile et des finitions plus lisses.

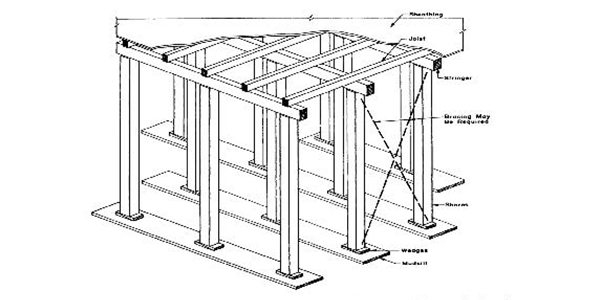

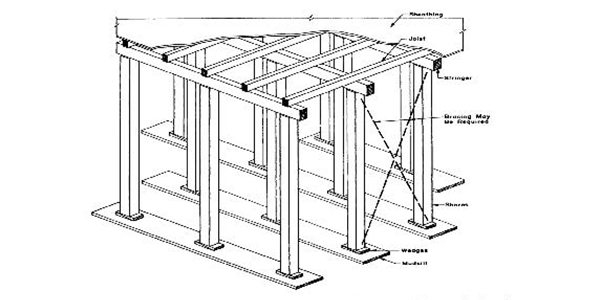

Coffrage pour les dalles

Le coffrage de la dalle prend en charge les coulées en béton horizontal:

- Détalonnage: des feuilles de contreplaqué (20 mm + d'épaisseur) reposent sur les solives en bois.

- Roites et limons: poutres en bois (par exemple, le bois 2x6 ou 4x4) de transfert vers des accessoires verticaux.

- Accessoires / étangés: les poteaux de bois réglables (ou les prises à vis métalliques dans certains cas) fournissent un réglage de la hauteur.

Remarque de sécurité: Assurez-vous que les accessoires sont uniformément espacés et préparés latéralement pour éviter l'effondrement.

Caractéristiques clés du coffrage basé sur le bois

Les systèmes traditionnels en bois et en contreplates offrent des avantages distincts:

- Cost-efficace: coûts initiaux faibles par rapport aux systèmes préfabriqués.

- Flexibilité: facilement personnalisée pour des formes, des courbes ou des conceptions personnalisées irrégulières.

- Accessibilité: le bois et le contreplaqué sont largement disponibles à l'échelle mondiale.

- Facilité de réparation: les composants endommagés peuvent être remplacés rapidement sur place.

- Durabilité: le bois est renouvelable et le contreplaqué peut être réutilisé plusieurs fois.

- Simplicité éprouvée: nécessite un minimum d'outils ou de formation spécialisés.

Limites:

- Assemblée et démantèlement à forte intensité de main-d'œuvre.

- La durée de vie plus courte par rapport aux systèmes métalliques.

- Sensible aux dommages à l'humidité s'ils sont non traités.

Optimisation du coffrage du bois pour l'efficacité

Pour améliorer les performances et réduire les déchets:

- Composants préalables: planifiez et coupez le bois / contreplaqué hors site pour gagner du temps.

- Réutiliser les matériaux: nettoyer et stocker les feuilles de contreplaqué correctement pour la réutilisation.

- Impermitation: enveloppez en contreplaqué avec des scellants pour prolonger sa durée de vie.

- Souffrein: Renforcez les formes avec des accolades en bois supplémentaires pour les versements lourds.

Étude de cas: coffrage du bois dans la restauration du patrimoine

Dans la restauration en 2022 d'une façade en brique du XIXe siècle en Angleterre, les entrepreneurs ont utilisé des coffrages de bois traditionnels pour reproduire les corniches ornées. Le contreplaqué était façonné en courbes personnalisées, tandis que les cadres en bois ont assuré la stabilité. Le projet a mis en évidence l'adaptabilité inégalée de Timber pour la correspondance des conceptions historiques - quelque chose de systèmes métalliques rigides ne pouvait pas réaliser.

Pourquoi le coffrage du bois prospère toujours

Malgré des alternatives modernes, le coffrage en bois et en contreplations excelle:

- Projets budgétaires: idéal pour les maisons résidentielles, les constructions rurales ou les travaux à petite échelle.

- Designs personnalisés: éléments sculpturaux, arches ou restaurations du patrimoine.

- Environnements à faible technologie: adaptés aux régions ayant un accès limité à des équipements avancés.

Conclusion

Le coffrage traditionnel en bois et en bois reste la pierre angulaire de la construction en béton. Sa simplicité, son adaptabilité et son faible coût le rendent indispensable pour les projets hiérarchisant la personnalisation sur la vitesse. En maîtrisant des techniques comme le placement de la forme de forme, le scellage en contreplaqué et le contreventement, les constructeurs peuvent obtenir des résultats de haute qualité tout en restant dans le budget.

Pour les entrepreneurs et les amateurs de bricolage, cette méthode éprouvée plie la pratique et l'artisanat, prouvant que parfois les «anciennes manières» sont toujours les meilleures.

FAQ

Comment empêcher le nid d'abeille en béton avec des formes de bois?

- Assurez-vous des joints serrés entre les feuilles de contreplaqué et vibrez soigneusement le béton pendant le versement.

Le coffrage du contreplaqué peut-il être réutilisé pour les finitions en béton exposées?

- Oui, mais utilisez un contreplaqué de haut niveau et poncé et appliquez un agent de libération avant chaque coulée.

Quelle est la hauteur maximale pour le coffrage du mur de bois?

- Pour le contreplaqué 19 mm, limitez la hauteur non soutenue à 1,8 m. Utilisez un contreplaqué plus épais ou réduisez l'espacement des goujons pour les murs plus hauts.

En savoir plus

Coffrage | Concret, barbe à barres, étouffant ---- Britannica

Qu'est-ce que le coffrage? ---- Glossaire de Kreo